Warborough

Warborough

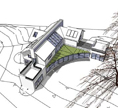

Replacement for a former bungalow that was a long-term family home…

Background:

- Replacement for the former bungalow, where the family had lived for 20 years at Warborough, near Didcot, Oxfordshire.

Delivery:

- The site lies on the edge of a Conservation Area and within a residential area.

- Height was restricted to match neighbouring buildings.

- The four bed house is very large and provides 377sqm / 4050sqft of space.

- The external appearance features a reconstituted stone plinth with a cedar clad upper storey. The pitched roofs are slate, flat roofs are polyroof, some with sedum covering.

- Because of the clay subsoil base and two willow trees in the garden, the house sits on piled foundations. The ground floors are beam and block and the first floor uses a precast concrete plank system. This allowed high levels of insulation, and a thermal mass at ground and first floor onto which the underfloor heating system is laid.

- Walls are stone outer leaf, full fill cavity and block work inner leaf with powder coated aluminium windows.

- Windows were budgeted at £25,000, but the lowest tender came back at £40,000. There were many delays, including waiting for all window spaces to be built and measured before manufacture commenced, and some damage having to be made good by the manufacturer in Germany.

- Insulation levels for all sections of the building were 25% higher than the requirements of Building Regulations.

- The building’s hot water and heat is from air source heat pumps. There were initial problems including getting the correct thermostat to tally up with the correct room, and fans freezing when severe snow blew into the air source heat pump intake – all since rectified and the system is now running well.

- Some rainwater is harvested for use in the garden, cloakroom toilet and washing machine.

- The main structure was built by a main contractor with the owner project managing subcontractors for finishes and kitchen.

- The advantages are living sustainably and an improved lifestyle – the owners are very proud of their home.

- The property benefits from lower running costs.

- The layout enables disabled access, including a wider than average front door, steps with wider and deeper treads and lower risers, one step access to all rear gardens, parking close to front door and level access from car to house.

Finance:

- The plot was already owned. Typical plots in the area would have cost over £250,000.

- The owner used the money from the sale of his company to fund the build.

- Build costs were £625,000 (£1,650 per square metre).

- The original budget was £450,000 but the house grew in size (costing an extra £15,000). The original gravelled driveway was changed to resin bonded (adding another £15,000). Kitchen and bathroom spec increased (an extra £27,000), and the kitchen supplier went bust taking £30,000 with him. A sauna was added at £4,000. All these, and many other extras, added £175,000, taking the budget up to £625,000.

- The completed home is now valued at £1.5m.

Timescale:

- 2008 – Planning permission granted.

- May 2009 – Existing house demolished.

- June – Aug 2009 – Foundations and ground floor.

- Dec 2009 – Steelwork for upper floor, and pitched roof in place.

- Jan – July 2010 – Windows and doors, from manufacture to installation.

- July – Sep 2010 – Decoration and external works to completion.

Learning Points:

- Thorough ground investigation is essential, as unexpected piling costs can be high.

- Ensure you have very closely defined sub-contract packages – especially for windows and doors. Keep the design simple. Set deadlines with penalties in the contract and keep chasing the suppliers.

- Either keep to your original budget and buy kitchens/sanitary ware/floor finishes to suit, or have more money available to exceed the original spec.

- Allow time for all the final snagging items.